Offering forged parts based on energy efficiency, knowledge transfer and respect for all.

THE ITON DIFFERENCE

PRODUCE BETTER, CONSUME LESS

Thanks to our forged blanks made from solid metal, we significantly reduce consumption of materials and machining time.

OUR EXPERTISE

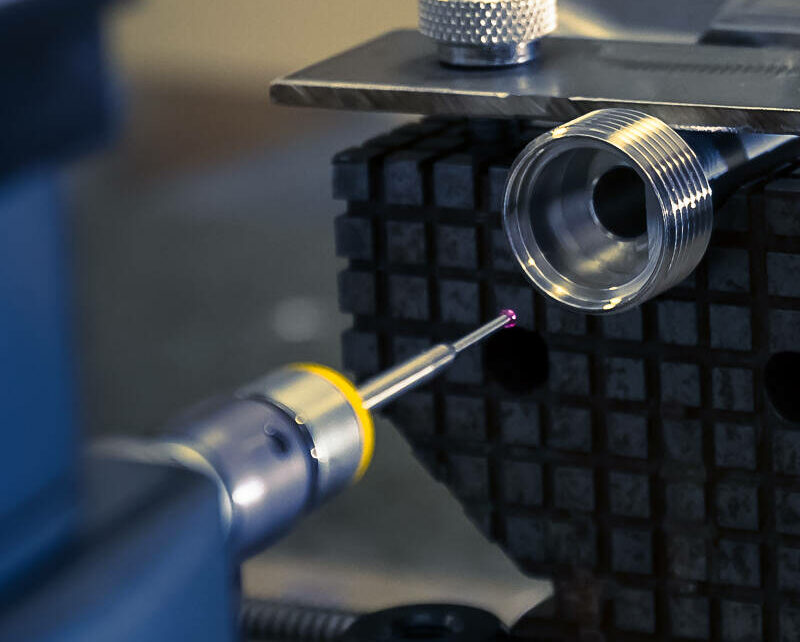

Combining material strength and technical precision

CONCEPT ITON designs and manufactures technical parts in steel, stainless steel and superalloys, from 500g to 20kg, in small- and medium-sized production runs.

Our closed-die forged blanks are used to create precise, reliable, material-optimised parts that meet the requirements of the most demanding industrial sectors.

1.4404

before machining

OUR AREAS OF EXPERTISE

- Traditional forging and flashless forging

- Precision machining

- Tool design

- Integrated design office

- End-to-end process (design, forging, machining, quality control)

1.4404

after machining

A SMALL-SIZED COMPANY

Rare expertise passed on a daily basis

Behind every part are experts: blacksmiths, machinists, toolmakers, quality technicians, operators and trainees.

CONCEPT ITON IS COMMITTED TO :

- Ongoing education

- Passing on knowledge

- Integrating young people through work-based training

- Respect and safety for all

THE ITON TEAM

QUALITY

Technical parts for the most demanding sectors

Our products are used in the industrial and food-grade plumbing, the pharmaceutical, chemicals, energy and shipbuilding industries, and in many other markets.