Qualité & Conformité

HIGH STANDARDS AT THE HEART OF EVERY PART

At Concept Iton, quality is not a final stage of the process: it’s a manufacturing principle, present at every stage—forging, machining, finishing and inspection.

Our customers operate in sectors in which failure is not an option.

So we integrate quality as early as the design stage, with complete control over the production chain.

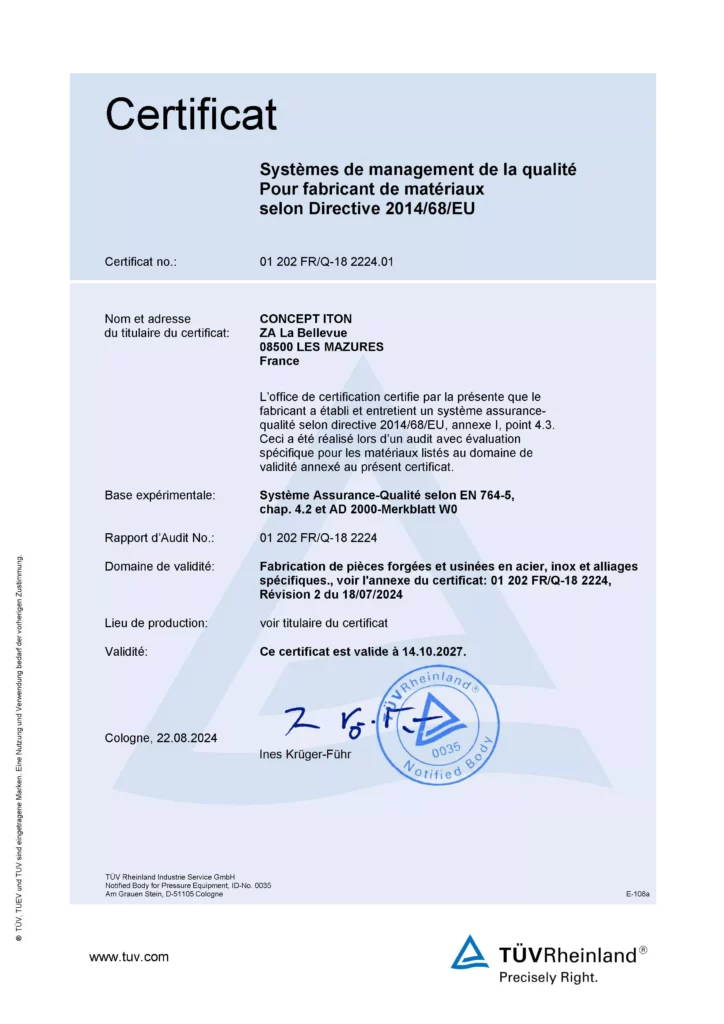

Many of the parts produced by Concept Iton are designed to be used in pressurised or safety-critical environments.

Our forging and machining practices are structured to meet the requirements of the European Pressure Equipment Directive (PED/AD).

This requires:

- a high level of traceability,

- rigorous checks on geometries,

- materials appropriate to mechanical constraints,

- constant dimensional stability,

- documented and validated procedures.

We regularly work with customers for whom PED/AD compliance is a critical part of their industrial processes.

A strict set of information is recorded for each part:

- material batch,

- forging parameters,

- tools used,

- machining programmes,

- operators,

- checks carried out,

- final compliance.

This traceability ensures reproducibility, transparency and compliance with the most demanding requirements.

Our checks include:

- dimensional measurements (internal/external),

- surface finishes,

- checks on narrow tolerances,

- checks on functional dimensions,

- compliance with plans.

Optimised forged blanks, particularly for circular parts, result in:

- normal jaw clamping,

- no draft,

- no parting lines,

- better machining performance and precision.

These characteristics naturally improve the final quality and limit the risk of deviations between production runs.

Our parts, which are mainly made of:

- stainless steel,

- Hastelloy,

- Inconel,

- Monel,

- specific superalloys,

require a controlled approach to ensure stability and performance.

Our processes ensure:

- consistency in surface finishes,

- repeatability of production runs,

- strict compliance with tolerances,

- reduced deviation between parts.

Quality is also evident in preparation:

- a well-designed forged blank,

- narrow tolerances from the forging stage onwards,

- a facilitated machining stage,

- less material, less effort for tools and more stability.

The "Iton Difference" is therefore a quality initiative as well as a technical advantage.

Before shipment, each part is the subject of:

- complete dimensional checks,

- visual checks,

- approval of material criteria,

- compliance of documents with the customer’s requirements.

For parts that are to be used in pressurised equipment, we strictly comply with the documentation and quality assurance requirements set out in the PED.