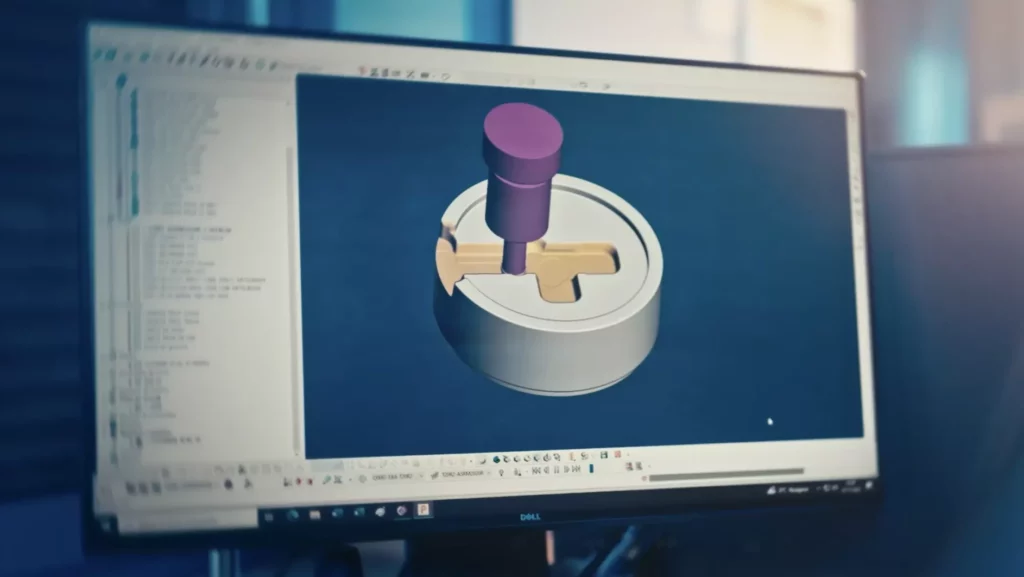

PRECISION MACHINING

TECHNICAL PARTS MACHINED WITH RIGOUR, CONSISTENCY AND EXPERTISE

Machining is a key aspect of Concept Iton’s expertise.

It enables the blank, which is either forged or supplied by the customer, to be transformed into a finished technical part that meets the dimensional and functional requirements of the most demanding sectors.

Thanks to our expertise and modern resources, we offer consistent precision, controls over cycle times, surface finishes tailored to your needs and perfect long-term reliability.

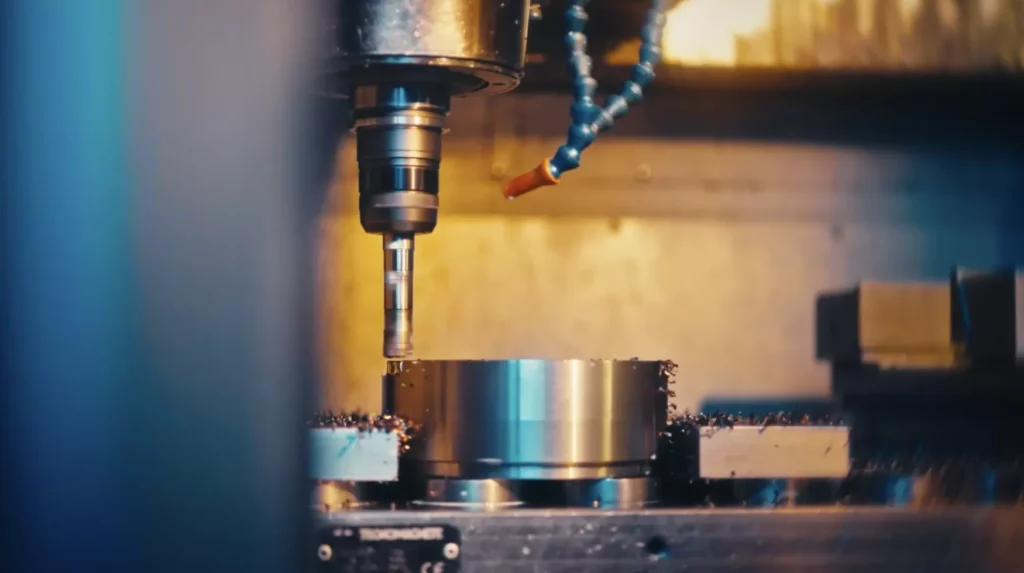

AN AUTOMATED, HIGH-PERFORMANCE AND VERSATILE FLEET OF MACHINERY

Our fully automated machinery is designed to work with demanding materials such as stainless steel, Inconel, Hastelloy and Monel.

Our equipment:

- turns circular or complex parts,

- carries out multi-operation milling,

- offers repeatability of production runs,

- reduces intervention times,

- offers high geometric stability.

This level of automation ensures that the parts produced are regular, precise and controlled.

COMPLEMENTARITY BETWEEN FORGING/MACHINING: INTEGRATED PERFORMANCE

Where the shape of the part allows, machining a forged part offers significant benefits:

- less material to remove,

- less wear on tools,

- dimensions close to the final shape,

- increased productivity,

- improved mechanical stability.

Our blanks are designed to directly optimise machining work: diameters with no draft, simplified jaw clamping and regular geometries.

This complementarity between forging and machining is at the heart of Concept Iton’s performance.

EXPERTISE IN HANDLING DIFFICULT MATERIALS

The machining of stainless steel and superalloys requires precise technical strategies: choice of tools, heat management and optimised trajectories.

Our team has developed specific expertise that ensures consistency in dimensions, controlled surface finishes, reduced cycle times and a longer life for tools.

This expertise is the result of years of experience gained in working on highly critical parts.

3

levels of finish,

expertise

TOLERANCES & CHECKS

We offer:

- narrow tolerances appropriate to pressurised environments,

- regular checks on dimensions,

- surface finishes in line with expectations,

- read and interpret customers’ technical drawings.

EXAMPLES OF MACHINED PARTS

We machine:

- valves,

- valve seats,

- circular components,

- plumbing components,

- parts for oxygen therapy devices,

- parts subjected to pressure, heat or corrosion.