THE FORGE

shaping the materials,

building performance

Blacksmithing is at the heart of Concept Iton’s expertise.

It is in the forge that the material is shaped, the fibre structure is oriented and mechanical performance is developed.

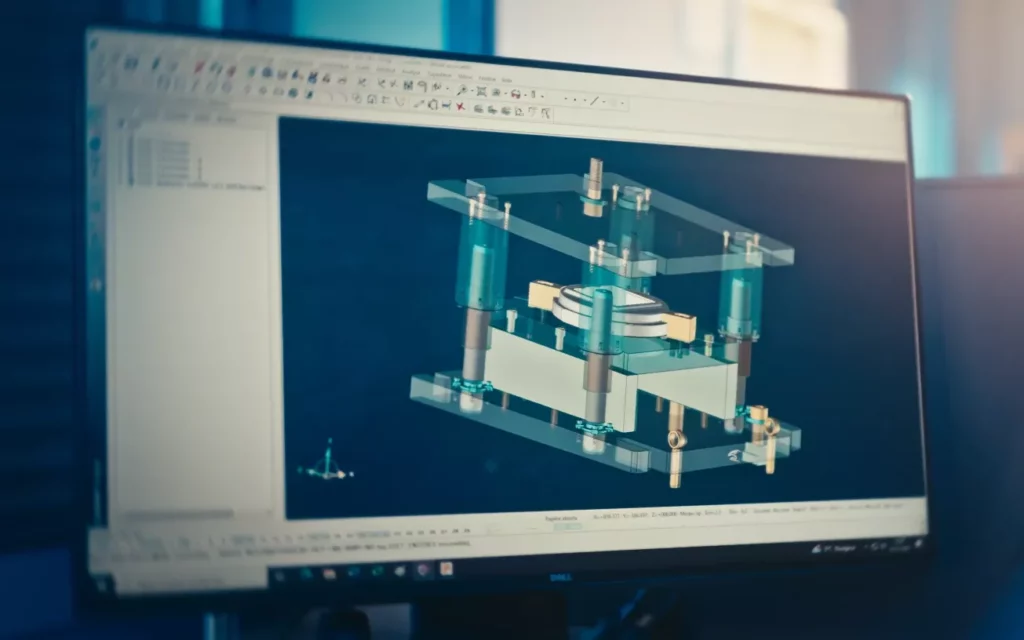

We design and produce all the forging tools we need to manufacture your parts in-house.

IN-HOUSE TOOL DESIGN AND PRODUCTION

Our design office designs and manufactures :

- the dies,

- the tools,

- technical solutions tailored to the most complex parts.

This expertise allows us to:

- optimise materials,

- adapt shapes to future machining,

- carry out technology transfer (conversion from mechanically welded → forged).

We also carry out technical and economic analysis to determine the benefits of forging.

Robust and adaptable, it can be used for a wide variety of parts and production runs.

Our speciality.

This process produces blanks that are close to the final dimensions, with:

- material savings of between 10 and 50% depending on the shape,

- a reduction in machining times,

- diameters without any draft or parting lines,

- excellent repeatability.

We forge:

- parts weighing between 500g and 20kg,

- in steel, stainless steel and superalloys (Hastelloy, Monel, Inconel, etc.),

- up to 250mm in diameter,

- in small and medium production runs.

Forging is the only process that:

- respects and orients the fibre structure,

- guarantees a sound part with no internal porosity

- strengthens mechanical characteristics,

- guarantees exceptional stability even where there are significant constraints.

Each press and each die directly contribute to the final robustness.

For circular or symmetrical parts, closed-die forging is used to produce blanks that:

- differ from the final dimensions by only 1mm or less,

- are perfectly suited to machining,

- do not have any draft,

- have no parting lines.

The resulting tolerances are narrow:

- ± 0.25mm in terms of external diameter,

- ± 0.50mm in terms of internal diameter.

These geometries allow normal jaw clamping and reduce tool wear.

Choosing a forged part is generally more economical than machining from a solid block where:

- the part exceeds a certain diameter,

- the geometry is circular or symmetrical,

- mechanical performance is critical,

- the cost of materials needs to be optimised.

To learn more about the direct impact on costs, materials and machine time, read about the Iton Difference.

We forge parts for:

- industrial and food-grade plumbing,

- the chemicals and pharmaceutical industries,

- the oxygen therapy industry,

- the shipbuilding industry,

- pressurised systems (PED approval).

Do you have a forging project?

Our design office is here to support you in the design and optimisation of your parts.