THE ITON DIFFERENCE

WHEN THE RAW FORM ALREADY SHAPES THE FINAL PERFORMANCE

The Iton Difference is at the heart of Concept Iton’s value proposition.

It is based on a simple idea: design the part at the inception of the project, at the forging stage, to optimise all subsequent stages, machining, production time, materials, costs and mechanical performance.

At Concept Iton, coherence between forging, machining and checks is not a succession of different areas of expertise: it is an integrated system.

Most parts can be designed to:

- reduce the amount of material removed during machining,

- limit waste,

- reduce the material footprint,

- get as close as possible to the final geometry as early as the forging stage.

A well-engineered forged part can be designed to within a few millimetres of the final dimensions, naturally reducing downstream interventions.

A geometry already close to the final result means:

- less processing,

- less effort for the tool,

- lower heat generation,

- fewer machine stoppages.

The result is a shorter, more stable cycle, ideal for small and medium-sized production runs where every minute counts.

A “smart” machining process, designed at the forging stage:

- reduces wear on tools,

- reduces breakage risks,

- ensures greater production consistency.

This results in lower overall costs and, above all, a level of accuracy that remains stable over the entire production run.

A forged blank retains the material’s fibre structure, unlike machining from a solid block.

This fibre structure:

- strengthens the mechanical properties,

- increases resistance to pressure,

- improves performance over time and in harsh environments.

This stability is invaluable in sectors in which there is no room for uncertainty.

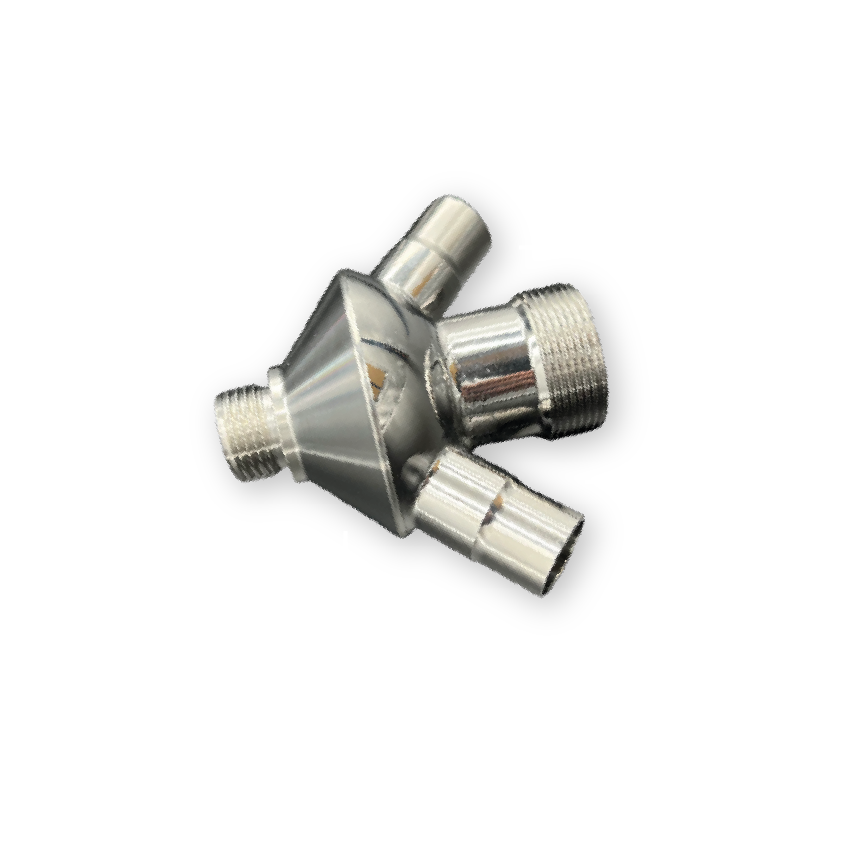

The Iton Difference means that we also have the capacity to offer three levels of finish:

- Rough-forged

- Machined

- Mirror polished (depending on needs)

Three levels, a single point of contact, full continuity.

Each part is unique: geometry, materials, conditions of use, pressure constraints, specific industry requirements.

Our role is to guide you towards the most efficient process.

- If the part would benefit from being forged → we suggest an optimised blank.

- If machining from a solid block is more appropriate → we adapt our trajectories and our tools.

There is no absolute truth: there is analysis, experience, and the right choice for your project.